On bitterly cold northern power transmission lines, a critical fitting suddenly undergoes brittle fracture; in petrochemical installations at tens of degrees below zero, pressure-bearing connection components crack without warning—the root cause of these alarming low-temperature failure accidents often points to a mismatch between material and environment.

- The “Severe Test” of Low Temperatures on Fitting Materials

When temperatures plummet, subtle microstructural dramas unfold within metals:

Precipitous Drop in Toughness: The movement of dislocations in body-centered cubic (BCC) structured carbon steels and low-alloy steels (e.g., 35 Steel, 45 Steel) is hindered at low temperatures, leading to a sharp decline in toughness.

The Ductile-to-Brittle Transition Temperature (DBTT) Trap: Every material has a critical temperature below which the risk of brittle fracture increases dramatically.

Amplification of Residual Stress Effects: Stresses introduced by welding or cold working are more likely to induce crack propagation at low temperatures.

Simplified Explanation: Imagine certain metal materials at low temperatures are like frozen, rigid modeling clay or a piece of ice.

They become “harder” (yield strength increases): The lower the temperature, the harder and more difficult this “clay” is to bend or deform (yield strength increases sharply), akin to modeling clay becoming stiff and hard to manipulate in winter.

They become “brittle” (fracture strength remains largely unchanged): However, their ability to resist being directly snapped or pulled apart (fracture strength) does not significantly strengthen with the cold; it essentially stays the same. Like a piece of ice, no matter how much you freeze it, it remains prone to shattering.

The Dangerous Critical Point (Brittle Transition Temperature): When the temperature drops to a specific low point, a dangerous phenomenon occurs:

The material becomes extremely difficult to deform (its yield strength becomes very high). But meanwhile, the critical force required to snap/pull it apart (fracture strength) remains at its original level.

“Too Hard” Leads to “Brittle” Fracture: The consequence is that when you apply force to pull or compress it:

Before it even has a chance to deform (show signs of “yielding” like elongation or bending), The applied force has already reached and exceeded its fracture limit! Crack! It breaks suddenly, like ice or glass, without any warning or prior deformation. This is the brittle fracture we observe.

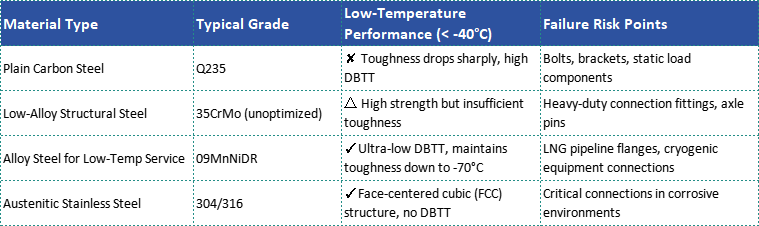

- Performance of Different Materials on the Low-Temperature Battlefield

Note: Medium-carbon alloy steels like 35CrMo require quenching and tempering heat treatment to refine the microstructure and form tempered sorbite, which can potentially improve low-temperature toughness. Untreated 35CrMo faces brittle fracture risks at temperatures as high as -30°C.

- Three Technical Strategies to Overcome Low-Temperature Failure

Material Composition Optimization

Strictly control P, S impurity content (≤0.015%) to reduce grain boundary embrittlement phases.

Add elements like Ni, Mn (e.g., 3.5Ni steel) to suppress the ductile-to-brittle transition.

Employ ultra-clean smelting technology to enhance material homogeneity.

Microstructural Control

Achieve fine carbide particles and uniform sorbite structure through quenching and tempering.

Perform stress relief annealing on welded components to eliminate residual stress concentration.

Avoid undissolved ferrite caused by insufficient quenching or improper tempering.

Structural Design Defense

Use rounded transitions (R≥5mm) at key load-bearing points to reduce stress concentration.

Select fine-pitch threads for bolt connections to improve preload uniformity.

Add damping/vibration-absorbing structures at points subjected to vibrational loads.

- Golden Rules for Engineering Practice

Material Qualification: Mandate impact energy ≥ 27J at -50°C (per ASTM A370).

Process Monitoring: Record heat treatment curves in real-time to ensure adequate tempering.

In-Service Inspection: Conduct regular magnetic particle/ultrasonic testing to detect early-stage cracks.

Case Study – A Siberian Power Transmission Project: Replacing plain carbon steel fittings with optimized, heat-treated 35CrMoA (impact energy AKV ≥ 40J at -45°C) resulted in zero low-temperature failures over ten years of operation, reducing maintenance costs by 70%.

In northern Canada, winter temperatures can reach -50°C; it is essential to select materials capable of withstanding extreme cold! Cost control must be considered, as such cryogenic-resistant materials may be more expensive.

Conclusion

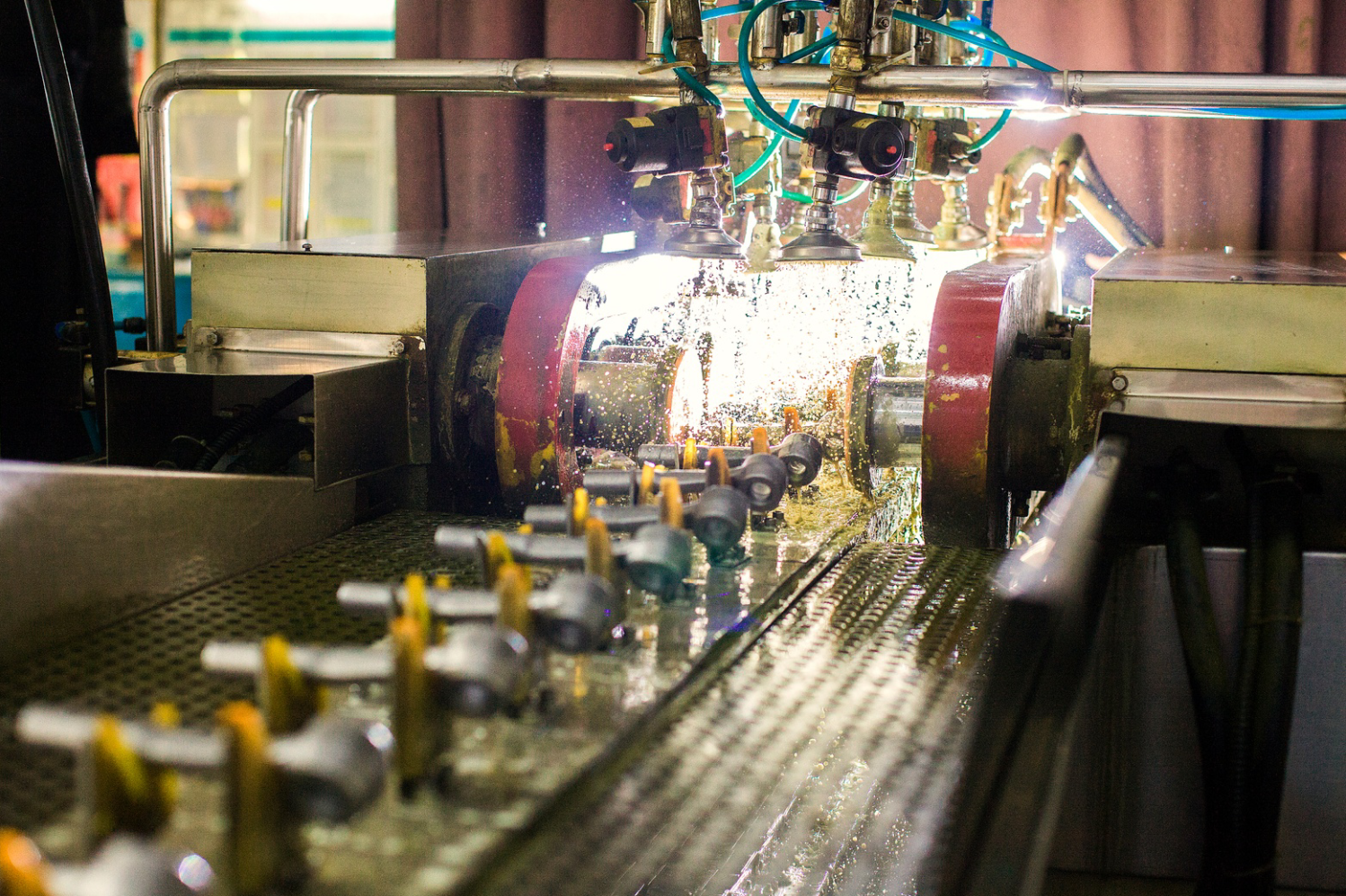

When cold fronts become the “ultimate examiner” for fittings, materials science is the key to solving the challenge. From composition design at the steelmaking furnace, to process control in the heat treatment workshop, and down to the detail optimization by structural engineers—precise collaboration at every stage builds a collective safety barrier against low temperatures. Tengtop uses reliable materials, and its products offer excellent cryogenic resistance while passing stringent low-temperature impact tests. Looking ahead, with the advancement of polar region development and deep-space exploration, breakthroughs in special low-temperature materials (such as high-entropy alloys, metal matrix composites) will open up broader safety boundaries for us.