As night falls, an inspector uses a headlamp to check the split pin and nut of a U-bolt one last time. The hum of a distant substation and the glittering city lights all depend on the stability of this U-shaped piece of metal.

In the vast power grid, perched on hundred-meter towers, there is a small, often overlooked component—shaped like a “U,” threaded at both ends, and quietly suspending the insulator string. This is a key connecting piece in power line hardware: the U-bolt, known within the industry as the “first piece” of the tower cross-arm.

Never underestimate this unassuming metal part. Veteran line workers with thirty years of experience know all too well: if it fails, it can cause anything from severe line sway to large-scale blackouts, potentially leading to economic losses in the tens of millions. Today, let’s dive deep into this “silent guardian” of the power grid.

01 Power Outage Scare: A Chain Crisis Triggered by a Single Bolt

A typical incident occurred last year in a southern region: a 35kV line suddenly tripped. During troubleshooting, the problem was traced to the connection point of the suspension insulator string—a U-bolt with cracks.

Further investigation revealed the truth: the area experienced frequent wind-induced deflection, but the installed U-bolts were standard types, with lateral load capacity insufficient for local wind loads. Even worse, installers had directly connected the bolt to plate-type hardware, resulting in point contact and uneven stress distribution.

This was no isolated case. Statistics show that over 60% of suspension point failures in windy areas are related to connector failures, with U-bolts often being the first link in the failure chain. During strong winds, insulator strings sway violently, subjecting the bolt’s thread roots to complex alternating bending stresses, making them highly prone to fatigue cracks.

02 Two Core Types: Choosing Wrong Plants Hidden Risks

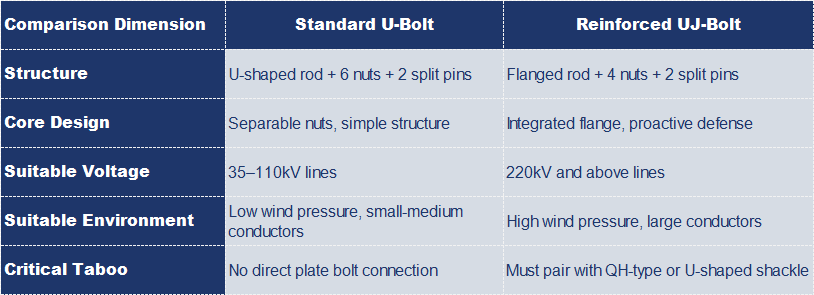

Many procurement or maintenance personnel hold the misconception: “Aren’t all U-bolts the same? Just pick a sturdy one.” In reality, different voltage levels and line scenarios require specific models.

The standard U-bolt is the “basic model,” consisting of a U-shaped rod, six nuts, and two split pins. It suits 35–110kV lines, especially in areas with low vertical loads and minimal wind deflection, such as suburban distribution networks and suspensions for small to medium-sized conductors.

However, two “critical taboos” must be remembered: First, it must never be directly connected to plate-type hardware bolts, as this restricts lateral movement and concentrates stress. Second, it must never be directly connected to a QP-type ball-eye shackle, as this creates point contact, stress concentration, and highly uneven load distribution.

The reinforced UJ-bolt, on the other hand, is the “heavy-duty option” designed for harsher conditions. Its two lower nuts are forged into an integrated “flange” with the rod. This clever design ensures that during wind deflection, lateral loads are borne by the flange as a support point, protecting the threads from bending damage.

Yet it also has specific requirements: it must be paired with a QH-type ball-eye shackle featuring an elongated oval inner hole or an additional U-shaped shackle adapter. It cannot be connected to a Q-type ball-eye shackle.

To clearly illustrate the differences, here’s a comparison of the two bolts’ core features:

03 Manufacturing Standards: “Cost-Saving” Shortcuts to Avoid

Choosing the right type is only the first step—product quality is equally critical. In manufacturing, two seemingly “material-saving” practices are strictly prohibited: rod reduction and reduced thread root diameter.

These processes severely weaken the bolt’s load-bearing cross-section and thread strength, becoming hidden threats to line safety. Proper products should ensure dimensional accuracy through standardized molds and optimized punch structures, eliminating variations from manual bending.

Material selection also matters: ordinary carbon steel Q235A meets basic needs, but in corrosive environments or heavily loaded lines, high-strength steel like Q345B or stainless steel is required. Surface treatment typically involves hot-dip galvanizing, with zinc layer thickness directly affecting service life in humid or industrially polluted areas.

04 Practical Selection: Four Steps to Choose the Right Bolt

For specific projects, how do you scientifically select a U-bolt? Remember this four-step approach:

- Assess Load Environment: Collect data on maximum wind speed and ice zone ratings for the line location to calculate combined loads. For large conductors (400mm² and above) or multi-bundle conductors, prioritize reinforced types.

- Confirm Connection Interface: Check tower cross-arm connection hole dimensions and thickness, and verify existing shackle models. If existing hardware uses QP-type shackles, replace them with QH-type or add a corresponding tonnage U-shaped shackle.

- Evaluate Corrosion Risk: In coastal, industrial, or high-humidity areas, choose corrosion-resistant materials or products with thicker zinc coatings. While initial costs may rise by 15%–30%, maintenance cycles can extend by 2–3 times, lowering lifecycle costs.

- Set Safety Margins: For critical transmission corridors or sections crossing railways and highways, consider upgrading one level above standard specifications to add an extra layer of grid security.

05 Split Pin: The Last Line of Defense You Should Never Skip

During installation, one small but critical component is often overlooked—the split pin. Though tiny, it is the final safeguard against nut loosening.

Especially for reinforced UJ-bolts, the nuts above the flange must be securely locked with split pins. Gradual loosening due to wind vibration often starts here, and a single split pin can prevent this “butterfly effect.” During maintenance inspections, split pin condition should be a mandatory check item.

In a 500kV backbone line upgrade project, the engineering team replaced all standard U-bolts with reinforced types. Although unit costs rose by 40%, the failure rate dropped by 85%, eliminating the need for triennial tightening maintenance. Over five years, overall costs actually decreased by 22%.

When you see city lights stretching across the night sky, remember: behind them are thousands of correctly chosen and properly installed U-bolts. Silently suspended between towers, they guard the flow of electricity with their sturdy embrace.